Our History

SH Auto Parts has enjoyed the history of rapid growth and success since its establishment in 1978

In 1978, Mr. Shih-tung Chou found Shih Hsiang Auto Parts Co., Ltd. in New Taipei City, focused on automotive suspension and steering systems. It was the birth of today's globally operating company.

In 1989, Taichung plant established and occupies an area of more than 32,500 M2.

In 2001, Shanghai Pudong plant operated.

In 2002, the company built its own brand, "SH"

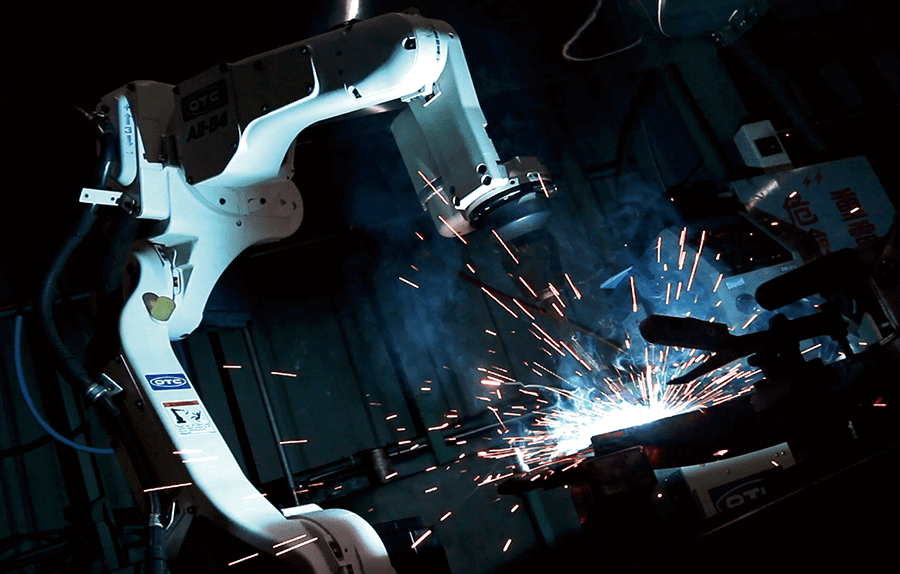

In 2021, Dounan plant will soon to be unveiled, with the implementation of indistrial 4.0 and the full automated production line.

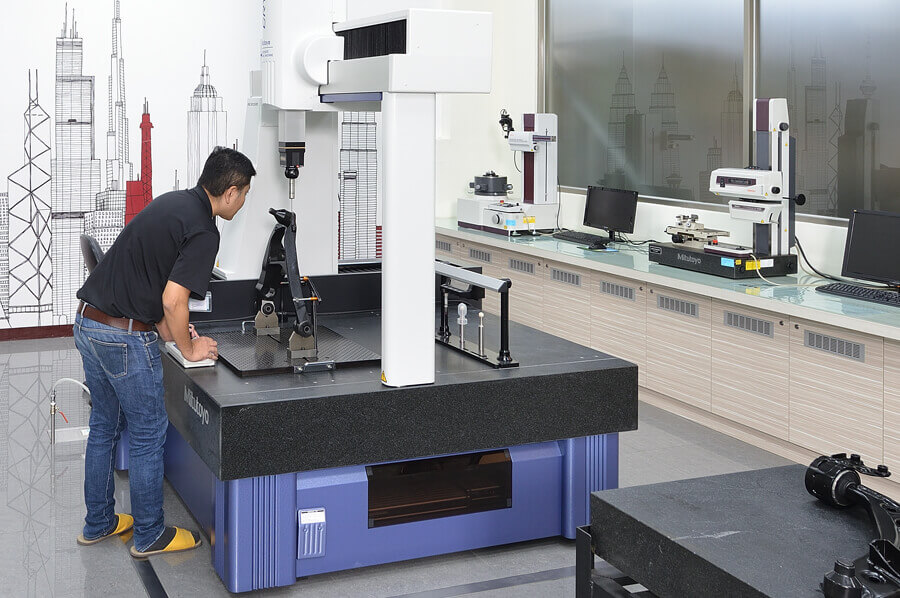

With the great effort devoted by our R&D team, SH company is known for being an innovation leader in the suspension system industry.

INNOVATION, PASSION, DESIGN, the company's very own mission statement can be found at the core of every product.

This is a benchmark that has been applied to the company for the past 40 years.

Apart from being a leading strategic supplier and strong partner to our global customers, Shih Hsiang also makes products available under its own brand, "SH" in fast-growing countries, including Asia, Middle East, Latin Americas, and Russia. The combination of continuous commitment to customising diversified items, deep integration with the global market and customer-oriented designs, the company becomes an outstanding expert and influencer in the industry.